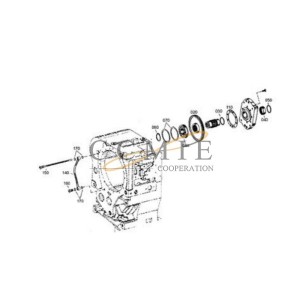

Wheel loader rocker zida zosinthira za XCMG Liugong wheel loader

rocker

Chifukwa pali mitundu yambiri ya zida zosinthira, sitingathe kuziwonetsa zonse pawebusayiti. Chonde khalani omasuka kulumikizana nafe kuti mupeze zinazake.

mwayi

1. Timakupatsirani zinthu zonse zoyambirira komanso zotsatsa pambuyo pake

2. Kuchokera kwa wopanga kwa kasitomala mwachindunji, kusunga mtengo wanu

3. Zigawo zokhazikika zokhazikika

4. Mu Time Delivery Time, ndi mtengo wampikisano wotumizira

5. Professional ndi pa nthawi pambuyo utumiki

kunyamula

Mabokosi a Carton, kapena malinga ndi pempho lamakasitomala.

kufotokoza

Ntchito ya tappet ndikutumiza kukankhira kwa kamera ku ndodo yokankhira kapena ndodo ya valve, kukankhira ndodo kapena valavu kuti mugonjetse mphamvu ya kasupe wa valve, ndipo nthawi yomweyo kunyamula mphamvu yotsatizana ndi camshaft pamene. imazungulira. Malo oyikapo ndi bowo lowongolera lomwe limabowoleredwa pagawo lolingana ndi silinda kapena mutu wa silinda, womwe nthawi zambiri umapangidwa ndi chitsulo cha nickel-chromium alloy cast iron or cold shock alloy cast iron.

1)Ma tappets wamba Pali mitundu itatu ya matepi wamba: matepi ooneka ngati bowa, ma cylindrical tappets ndi mtundu wa zodzigudubuza. Ma tappets opangidwa ndi bowa ndi ma cylindrical amatha kuchepetsa kulemera kwawo chifukwa cha mawonekedwe opanda kanthu; matepi amtundu wa roller amalumikizana pamzere chifukwa cha mawonekedwe olumikizana, ndipo odzigudubuza amatha kugudubuza momasuka, zomwe zingachepetse kuvala. Ma tappets wamba ndi zomangika zolimba ndipo sangathe kungochotsa chilolezo cha ma valve. Chifukwa chake, ma injini omwe amagwiritsa ntchito ma tappets wamba amayenera kusintha ma valve.

2) Makhalidwe a matepi a hydraulic: Ubwino waukulu wa matepi a hydraulic pa matepi wamba ndikuti amatha kuthetsa chilolezo cha valve ya injini popanda kusintha chilolezo cha valve; panthawi imodzimodziyo, matepi a hydraulic amathanso kuchepetsa phokoso lotumizira la makina a valve injini.

3) Mapangidwe a hydraulic tappet: thupi la tepi limalumikizidwa ndi thupi limodzi ndi chivundikiro chapamwamba ndi silinda, ndipo limatha kusunthira mmwamba ndi pansi pabowo la tappet la mutu wa silinda. Bowo lamkati ndi bwalo lakunja la manja onse atsirizidwa ndi pansi. Bwalo lakunja limafanana ndi bowo la kalozera pa tepi, ndipo dzenje lamkati limafanana ndi plunger. Onse akhoza kusuntha wachibale wina ndi mzake. Kasupe wobwezera amayikidwa pansi pa silinda ya hydraulic kuti akanikize valavu ya mpira kumpando wa valve wa plunger. Ikhozanso kusunga pamwamba pa tappet kuyandikira pafupi ndi cam pamwamba kuti athetse chilolezo cha valve. Pamene valavu ya mpira imatseka dzenje lapakati la plunger, tappet ikhoza kugawidwa m'zipinda ziwiri zamafuta, chipinda chapamwamba cha mafuta otsika kwambiri ndi chipinda chotsika kwambiri cha mafuta; valavu ya mpira ikatsegulidwa, chipinda chimapangidwa.

4) Mfundo yogwira ntchito ya tappet ya hydraulic Pamene poyambira mafuta pamtundu wa tappet imagwirizana ndi bowo lamafuta oblique pamutu wa silinda, mafuta mu makina opangira mafuta amalowa m'bowo lamafuta otsika kudzera pabowo lamafuta oblique ndi annular. thumba la mafuta. Mphepete mwachinsinsi kumbuyo kwa thupi la tappet imatha kutsogolera mafuta kumalo otsika kwambiri amafuta pamwamba pa plunger. Pamene cam imazungulira ndipo thupi la tappet ndi plunger zimayenda pansi, mafuta omwe ali mu chipinda cha mafuta othamanga kwambiri amapanikizidwa ndipo mphamvu ya mafuta imakwera. Pamodzi ndi kasupe wamalipiro, valavu ya mpira imakanikizidwa mwamphamvu pampando wapansi wa valavu ya plunger. Pamene chipinda cha mafuta othamanga kwambiri chimasiyanitsidwa ndi chipinda chochepa cha mafuta. Chifukwa madziwa ndi osasunthika, tappet yonse imasunthira pansi ngati silinda, kukankhira tsinde la valve kutseguka. Panthawi imeneyi, mafuta a tappet annular groove adagwedezeka ndi bowo la mafuta oblique, ndipo mafuta amasiya. Pamene tappet ifika pakatikati pakufa kwake ndikuyamba kusunthira mmwamba, pansi pa kasupe wapamwamba wa valve ndi cam pansi, chipinda chapamwamba cha mafuta chimatsekedwa ndipo valavu ya mpira sidzatsegulidwa. Tappet ya hydraulic imatha kuwonedwa ngati tappet yolimba mpaka ikwera. Mpaka cam ili mu bwalo loyambira ndipo valavu yatsekedwa. Panthawiyi, mafuta oponderezedwa omwe ali mu gawo lalikulu la mafuta amutu wa silinda amalowa m'chipinda chochepa cha mafuta a tappet kupyolera mu dzenje la mafuta. Nthawi yomweyo, kuthamanga kwamafuta m'chipinda chamafuta othamanga kwambiri kumatsika, ndipo kasupe wamalipiro amakankhira plunger m'mwamba. Mafuta opanikizika kuchokera ku chipinda chochepetsera mafuta amakankhira valavu ya mpira mu chipinda chapamwamba cha mafuta, kotero kuti zipinda ziwirizo zimagwirizanitsidwa ndikudzazidwa ndi mafuta. Panthawi imeneyi, pamwamba pa tappet akadali pafupi kwambiri ndi cam. Vavu ikatenthedwa ndikukulitsidwa, plunger ndi silinda ya hydraulic zimayenda molumikizana wina ndi mnzake kunjira ya axial, ndipo mafuta omwe ali muchipinda chamafuta opanikizika kwambiri amatha kufinya mchipinda chamafuta otsika kwambiri kudzera mumpata pakati pa silinda ya hydraulic. ndi plunger. Chifukwa chake, mukamagwiritsa ntchito matepi a hydraulic, palibe chifukwa chosungira chilolezo cha valve.

2. Ntchito ya ndodo yokankhira ndikutumiza kukankhira komwe kumaperekedwa kuchokera ku camshaft kudzera pa tappet kupita ku mkono wa rocker mu makina ogawa mpweya wa valve yapamwamba ndi camshaft yapansi. Kukankhira ndodo ndiye gawo losinthika kwambiri komanso lowonda kwambiri mu masitima apamtunda. Kapangidwe kake kamakhala ndi magawo atatu: mutu wa mpira wapamwamba kwambiri, mutu wa mpira wam'munsi ndi ndodo yopanda kanthu. Ndodo yokankhira nthawi zambiri imapangidwa ndi chitoliro chozizira chosasunthika, ndipo ena amapangidwa ndi duralumin. Pula yolimba yachitsulo nthawi zambiri imapangidwa kuti ikhale yonse ndi chithandizo chozungulira, kenako kutentha kutentha; mbali ziwiri za duralumin zinthu zolimba putter zimakhala ndi zothandizira zitsulo, ndipo pamwamba ndi pansi zimaphatikizidwa ndi shaft; mutu wa mpira wakale ndi Shaft imapangidwa lonse, ndipo malekezero awiri omalizawo amaphatikizidwa ndi tsinde mwa kuwotcherera ndi kusindikiza. Ngakhale pali kusiyana kwina mu mawonekedwe apangidwe, zofunikira za ndodo yokankhira ndizofanana, ndiko kuti, kulemera kwake ndi kukhazikika kwakukulu. Nthawi zonse, pofuna kuonetsetsa kuti tappet ikukwanira bwino, mkono wa rocker ndi tappet, cholumikizira chachitsulo chozungulira chimawotcherera kumapeto kumtunda kwa ndodo yokankhira kuti ifanane ndi mutu wa mpira wa rocker arm adjusting screw; Mu mpira wa concave.

3. Ntchito yaikulu ya mkono wa rocker ndikusintha njira yotumizira mphamvu. Mkono wa rocker ndi wofanana ndi mawonekedwe a lever, omwe amatumiza mphamvu ya ndodo yokankhira kumapeto kwa mchira wa tsinde la valve kukankhira valavu kuti atsegule; chiŵerengero cha kutalika kwa mikono iwiri (yotchedwa rocker arm ratio) imagwiritsidwa ntchito kusintha kukweza kwa valve, valve rocker arm Kawirikawiri, imapangidwa mu mawonekedwe a kutalika kosafanana. Dzanja la mbali ya valve ndi 30% mpaka 50% kutalika kuposa mkono womwe uli kumbali ya ndodo yokankhira, kotero kuti kukweza valavu yaikulu kungapezeke.

Nyumba yathu yosungiramo katundu1

Pakani ndi tumizani

- Aerial Boom Lift

- China Dampo Truck

- Cold Recycler

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Cholumikizira cha Forklift Sweeper

- Zigawo za Hbxg Bulldozer

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Zigawo za Liugong Bulldozer

- Zigawo za Sany Concrete Pump

- Sany Excavator Spare Parts

- Gawo la Injini ya Shacman

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Kulumikiza Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- Shantui Bulldozer Kukweza Cylinder Kukonza Kit

- Zigawo za Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Magawo a Shantui Bulldozer

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Wonyamula Sleeve

- Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Tow Truck

- Zigawo za Xcmg Bulldozer

- Zigawo za Xcmg Bulldozer

- Xcmg Hydraulic Lock

- Kutumiza kwa Xcmg

- Yuchai Engine Parts