Dalaivala kutsinde XCMG Liugong motor grader zida zosinthira

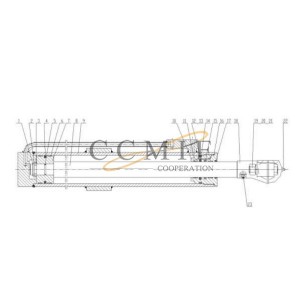

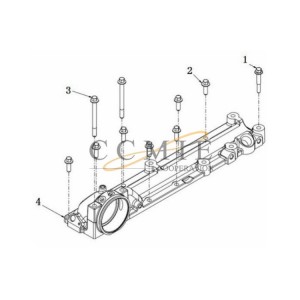

Dalaivala shaft

Chifukwa pali mitundu yambiri ya zida zosinthira, sitingathe kuziwonetsa zonse pawebusayiti. Chonde khalani omasuka kulumikizana nafe kuti mupeze zinazake.

Ubwino

1. Timakupatsirani zinthu zonse zoyambirira komanso zotsatsa pambuyo pake

2. Kuchokera kwa wopanga kwa kasitomala mwachindunji, kusunga mtengo wanu

3. Zigawo zokhazikika zokhazikika

4. Mu Time Delivery Time, ndi mtengo wampikisano wotumizira

5. Professional ndi pa nthawi pambuyo utumiki

Kulongedza

Mabokosi a Carton, kapena malinga ndi pempho lamakasitomala.

kufotokoza

Dalaivala-shaft ndi imodzi mwamagawo ofunikira a gawo loyendetsa makina omangira chassis. Imapindika movutikira, zolemetsa zolemetsa komanso zolemetsa zazikulu zikagwiritsidwa ntchito, zomwe zimafuna kuti theka la shaft likhale ndi mphamvu zotopa kwambiri, kuuma komanso kukana kuvala bwino. Moyo wautumiki wa theka-shaft sikuti umangokhudzidwa ndi dongosolo ndi kusankha kwazinthu pagawo lopanga zinthu, komanso njira yopangira zopangira komanso kuwongolera kwazinthu zopangirako ndizofunikira kwambiri.

Kusanthula kwaubwino wa njira ndi njira zowongolera popanga

1 Kudula ndondomeko

Ubwino wa blanking zidzakhudza khalidwe la wotsatira kwaulere forging akusowekapo ndipo ngakhale kufa forging. Zowonongeka zazikulu mu ndondomeko yosalemba kanthu ndi izi.

1) Utali wake ndi wosalolera. Kutalika kopanda kanthu ndi kotalika kwambiri kapena kwaufupi kwambiri, kutalika kwambiri kungapangitse kuti zojambulazo zikhale zabwino kwambiri mu kukula ndi zowonongeka, ndipo zazifupi kwambiri zingayambitse kusakhutira kapena kukula kochepa. Chifukwa chikhoza kukhala kuti choyimitsidwa chayikidwa molakwika kapena choyikapo chitha kukhala chotayirira kapena cholakwika panthawi yomwe simunatchulepo.

2) Kutsetsereka kwa nkhope yomaliza ndi yayikulu. Kutsetsereka kwakukulu kwapamtunda kumatanthawuza kuti kupendekera kwa kumapeto kwa malo opanda kanthu ponena za utali wakutali kumaposa mtengo wovomerezeka. Pamene malo otsetsereka a nkhope yomaliza ndi aakulu kwambiri, makutu amatha kupangidwa panthawi yopangira. Chifukwa chake chikhoza kukhala kuti mipiringidzo siimangiriridwa panthawi yotsekedwa, kapena nsonga ya dzino la band saw blade yavala mosadziwika bwino, kapena kugwedezeka kwa tsamba la band ndikochepa kwambiri, mkono wotsogolera wa makina ocheka sali ofanana. mzere wopingasa, ndi zina zotero.

3) Burr kumapeto kwa nkhope. Akamacheka zinthu za bar, ma burrs nthawi zambiri amatha kuwonekera pakupuma komaliza. Mabulangete okhala ndi ma burrs amatha kuyambitsa kutentha kwambiri komanso kuwotcha kwambiri akatenthedwa, ndipo ndi osavuta kupindika ndi kung'amba pakupanga. Chifukwa chimodzi n’chakuti macheka amakalamba, kapena mano a macheka atha, osati akuthwa mokwanira, kapena macheka ali ndi mano osweka; chachiwiri ndi chakuti liwiro la mzere wa macheka silinakhazikitsidwe bwino. Nthawi zambiri, tsamba la macheka latsopano limatha kufulumira, ndipo tsamba lakale limakhala lochedwa.

4) Ming'alu kumapeto kwa nkhope. Pamene kuuma kwa zinthu sikuli kofanana ndipo kulekanitsa kwazinthu kumakhala koopsa, ndikosavuta kutulutsa ming'alu yakumapeto. Kwa osasoweka ndi ming'alu yomaliza, ming'aluyo imakulanso panthawi yopangira.

Pofuna kuwonetsetsa kuti kulibe kanthu, njira zodzitetezera zachitika panthawi yopanga: musanatchule, tsimikizirani mtundu wazinthu, mawonekedwe, kuchuluka, ndi nambala yosungunulira ng'anjo (batch) molingana ndi ndondomeko ndi makhadi opangira. . Ndipo yang'anani khalidwe lapamwamba lazitsulo zozungulira zitsulo; kutsekedwa kukuchitika m'magulu malinga ndi nambala yopangira, mtundu wazinthu, chiwerengero ndi ng'anjo yosungunuka (batch), ndipo chiwerengero cha zomwe zikusowekapo chikuwonetsedwa pa khadi lotsata kuyendayenda kuti muteteze kusakanikirana kwa zinthu zakunja; Podula zinthuzo, dongosolo la "kuwunika koyamba", "kudziyang'anira" ndi "kuyang'anira" liyenera kukhazikitsidwa mosamalitsa. Kulolera kwa dimensional, malo otsetsereka ndi mapeto a burr opanda kanthu ayenera kuyang'aniridwa pafupipafupi malinga ndi zofunikira za ndondomekoyi, ndipo kuyenderako kumakhala koyenerera ndipo mawonekedwe a malonda amalembedwa. Dongosolo likhoza kusinthidwa pambuyo pake; panthawi yobisala, ngati zotsalirazo zapezeka kuti zili ndi zopindika, zipsera, ming'alu ndi zina zowoneka bwino, ziyenera kuuzidwa kwa woyang'anira kapena akatswiri kuti azitaya nthawi; malo opanda kanthu ayenera kukhala oyera, okhala ndi magiredi osiyanasiyana azinthu ndi nambala yosungunula ya Ng'anjo (mgulu), zofunikira ndi miyeso ziyenera kuyikidwa padera ndi zolembedwa bwino kuti asasakanizidwe. Ngati kulowetsedwa m'malo kuli kofunika, njira zovomerezeka zololeza zinthu ziyenera kutsatiridwa mosamalitsa, ndipo zida zitha kutulutsidwa pambuyo povomerezedwa.

2 Kutentha ndondomeko.

Njira yopangira ma semi-shaft imatenthedwa ndi moto awiri, billet yaulere imatenthedwa ndi ng'anjo ya gasi, ndipo ng'anjo yamoto imatenthedwa ndi ng'anjo yamagetsi yopangira magetsi, kotero kuwongolera njira yowotchera kumakhala kovuta komanso kovuta kwambiri; kuti tiwonetsetse kuti kutentha kuli bwino, tapanga izi:

Chitofu cha gasi chikatenthedwa, sichiloledwa kuti chizilipiritsa mwachindunji zinthuzo kumalo otentha kwambiri, ndipo siziloledwa kupopera lawi lamoto pamwamba pa chopanda kanthu; potentha mu ng'anjo yamagetsi, pamwamba pa chopanda kanthu sayenera kuipitsidwa ndi mafuta. Zomwe zimatenthetsa ziyenera kutsatiridwa molingana ndi zofunikira za njira zopangira zopangira, ndipo kutentha kwa kutentha kwa zidutswa 5-10 zazinthu zopanda kanthu kudzatsimikiziridwa kwathunthu musanasinthe kuti zitsimikizire kuti zowotcha ndizokhazikika komanso zodalirika. Billet silingapangidwe pa nthawi yake chifukwa cha zovuta za zida ndi zida. Ikhoza kukonzedwa ndi kuzizira kapena kunja kwa ng'anjo. Billet yokankhidwa iyenera kulembedwa ndi kusungidwa padera; billet ikhoza kutenthedwa mobwerezabwereza, koma chiwerengero cha kutentha sichikhoza kupitirira 3 nthawi. Kutentha kwazinthu pamene chopandacho chikutenthedwa kuyenera kuyang'aniridwa mu nthawi yeniyeni kapena nthawi zonse ndi thermometer ya infrared, ndipo mbiri yotentha iyenera kupangidwa.

3 Billet kupanga ndondomeko.

Zowonongeka zomwe zimachitika pakapangidwe ka billet zimaphatikizanso kutalika kapena kutalika kwa ndodo yapakatikati ya billet, zizindikiro za nyundo, komanso kusintha kolakwika. Ngati m'mimba mwake wa ndodo ndi zabwino kwambiri, zidzakhala zovuta kuziyika mu m'mimbamo pa kufa forging. Ngati ndodoyo ndi yaying'ono yolakwika, coaxiality ya forging ingakhale yosauka kwambiri chifukwa cha kusiyana kwakukulu kwa ndodo panthawi yakufa; Zolemba za nyundo za pamwamba ndi kusintha kosayenda bwino kungakhale kotheka Kutsogolera ku maenje kapena mapindikidwe pamwamba pa kupeka komaliza.

4 Njira yopangira ndi yodula kufa.

Zowonongeka zazikulu mu semi-shaft kufa forging process zimaphatikizapo kupindika, kudzaza kosakwanira, kupanikizika (osagunda), kusanja ndi zina zotero.

1) Pindani. Kupindika kwa theka-shaft kumakhala kofala kumapeto kwa flange, kapena pamzere wamasitepe kapena pakati pa flange, ndipo nthawi zambiri amakhala ngati arc kapena ngakhale ozungulira. Mapangidwe a khola amagwirizana ndi khalidwe la chopanda kanthu kapena chapakati chopanda kanthu, kamangidwe, kupanga ndi kudzoza nkhungu, kumangirira nkhungu ndi nyundo, ndi ntchito yeniyeni yopangira. Kupinda nthawi zambiri kumatha kuwonedwa ndi maso amaliseche pamene kufota kuli kotentha kwambiri, koma nthawi zambiri kumatha kuwunikira tinthu tating'ono mtsogolo.

2) Kudzazidwa pang'ono ndi kusakhutira. Kusakhutitsidwa kwapang'ono kwa ma forgings a theka-shaft makamaka kumachitika pamakona ozungulira akunja a ndodo kapena flange, zomwe zimawonetsedwa ngati ngodya zozungulira zimakhala zazikulu kwambiri kapena kukula kwake sikukwaniritsa zofunikira. Kusakhutitsidwa kudzetsa kuchepetsedwa kwa machining allowance of forging, ndipo ngati kuli koopsa, kukonzako kumachotsedwa. Zifukwa zosakhutira zingakhale: mapangidwe a billet apakati kapena opanda kanthu ndi osamveka, m'mimba mwake kapena kutalika kwake sikuli koyenerera; kutentha kwapang'onopang'ono kumakhala kochepa, ndipo madzi achitsulo ndi osauka; kudzoza kwa ufa wopangira sikokwanira; kudzikundikira kwa oxide sikelo mu difa cavity, etc.

3) Kusokonekera. Misalignment ndi kusamutsidwa kwa theka lakumtunda kwa forging wachibale ndi theka la m'munsi motsatira malo olekanitsa. Kuyika molakwika kukhudza momwe makinawo alili, zomwe zimapangitsa kuti pasakhale ndalama zokwanira zolipirira makina amderalo. Zifukwa zingakhale: kusiyana pakati pa mutu wa nyundo ndi njanji yowongolera ndi yaikulu kwambiri; kamangidwe ka forging die lock gap ndi wosamveka; kuyika nkhungu sikwabwino.

5 Njira yochepetsera.

Chachikulu khalidwe chilema mu yokonza ndondomeko yaikulu kapena m'modzi yotsalira kung'anima. Kuwala kwakukulu kapena kosiyana kotsalira kumatha kukhudza momwe makinawo amakhalira ndi kuwongolera. Kuphatikiza pa kuwonjezereka kwa gawo lachiwongoladzanja lakumaloko, zingayambitsenso kupotoka kwa makina, ndipo kungayambitsenso kudula chifukwa cha kudula kwapakatikati. Chifukwa chikhoza kukhala: nkhonya ya kudula kufa, kusiyana kwa kufa sikunapangidwe bwino, kapena kufa kumavala ndikukalamba.

Pofuna kupewa zolakwika zomwe tazitchula pamwambapa ndikuwonetsetsa kuti ma forgings ali abwino, tapanga ndikutengera njira zingapo zopewera ndi kuwongolera: kudziwa kukula koyenera kapena kwapakatikati kopanda kanthu kudzera pakuwunikanso kamangidwe ndi kutsimikizira ndondomeko; mu mawonekedwe a nkhungu ndi kutsimikizira siteji, kupatula nkhungu wamba Kuphatikiza pa masanjidwe a patsekeke, mlatho ndi kamangidwe ka silo, chidwi chapadera chaperekedwa pakutsata masitepe ndi mipata yotseka kuti mupewe kupindika ndi kusuntha molakwika, kuwongolera kokhazikika kwa njira ya kuphimba, kutenthetsa, ndi ma billets aulere, ndikuyang'ana pa oblique pamwamba pa billet. Ma degree ndi ma burrs kumapeto kwa nkhope, kusintha kwa masitepe apakati, kutalika kwa ndodo, ndi kutentha kwa zinthu.

Nyumba yathu yosungiramo katundu1

Pakani ndi tumizani

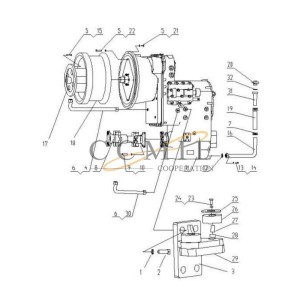

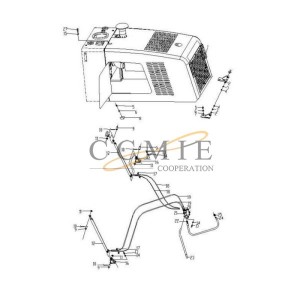

- Aerial Boom Lift

- China Dampo Truck

- Cold Recycler

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Cholumikizira cha Forklift Sweeper

- Zigawo za Hbxg Bulldozer

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Zigawo za Liugong Bulldozer

- Zigawo za Sany Concrete Pump

- Sany Excavator Spare Parts

- Gawo la Injini ya Shacman

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Kulumikiza Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- Shantui Bulldozer Kukweza Cylinder Kukonza Kit

- Zigawo za Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Magawo a Shantui Bulldozer

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Wonyamula Sleeve

- Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Tow Truck

- Zigawo za Xcmg Bulldozer

- Zigawo za Xcmg Bulldozer

- Xcmg Hydraulic Lock

- Kutumiza kwa Xcmg

- Yuchai Engine Parts